SlantTech

SlantTech

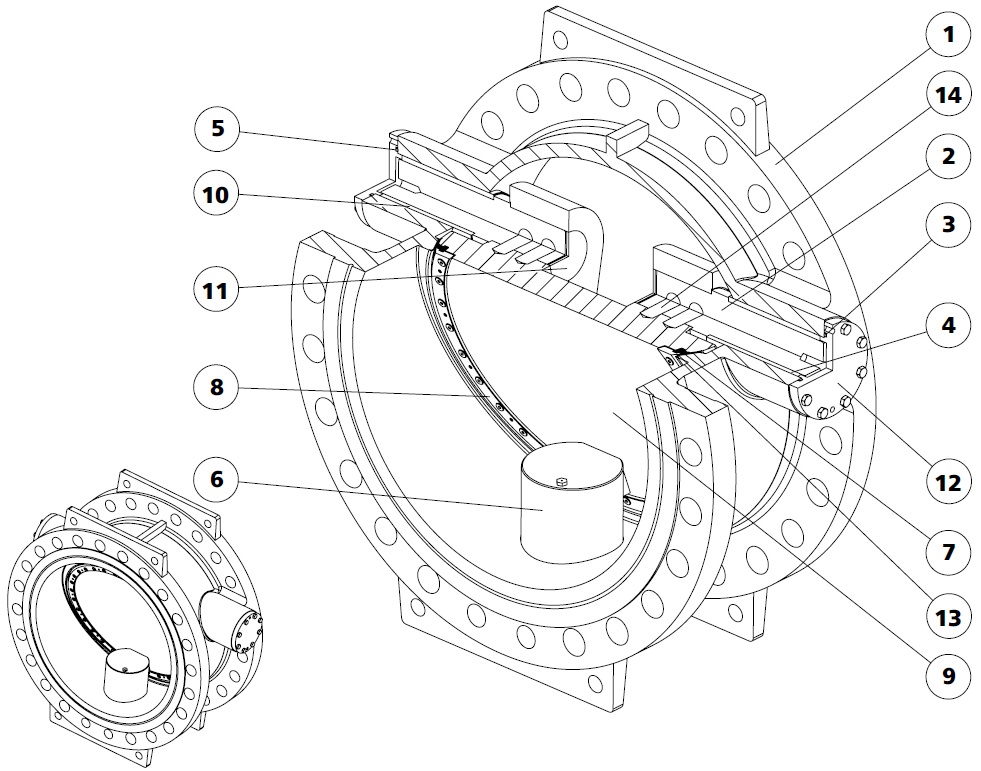

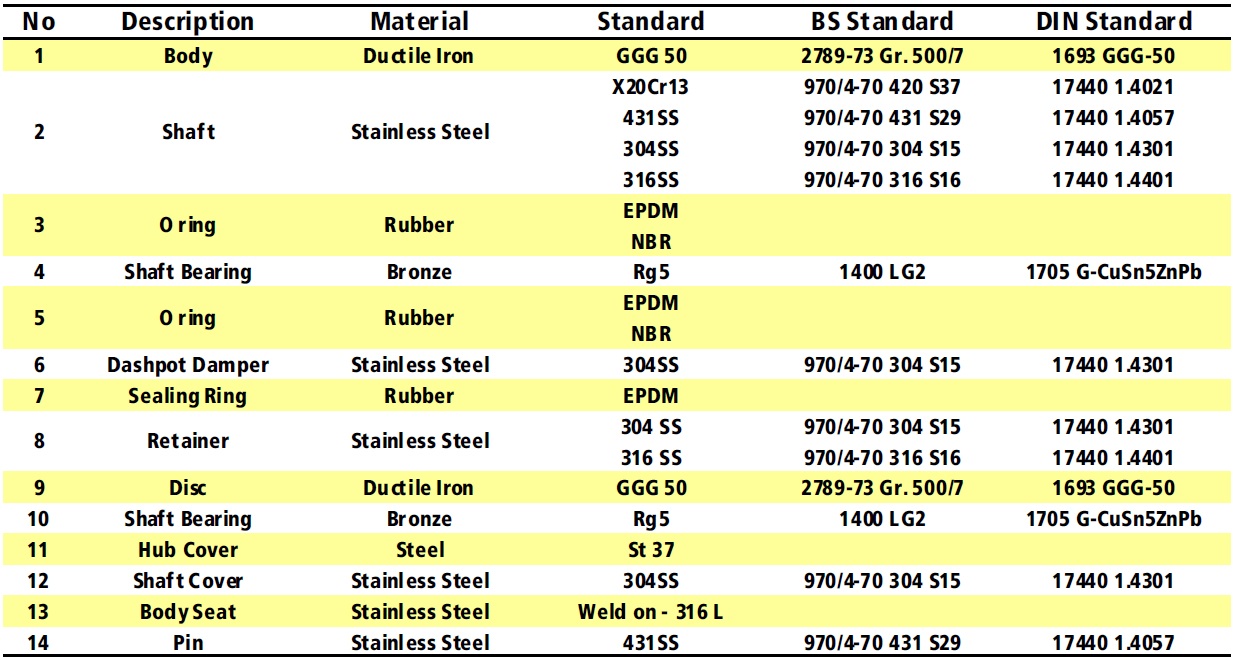

Slanted Seat Check Valve Double Offset, Heavy Duty Design. Highly Efficient, Rubber-to-metal sealing or Metal-to-metal sealing

The SlantTech is the result of AVM’s expertise in cutting edge valve technology, starting more than 5 decades ago.

AVM SlantTech Slanted Seat Check Valve was Designed for the water industry, taking into Account the latest development and know-how.

General advantages of Tilting Disc Check Valves:

- Functional light design:

a – Cost effective in purchase: Light and compact design results in a comparatively good price against other valve types

b – Cost effective during installation: Light design allows easy handling and installation

c – Cost effective in use: Problem free designs

d – Cost effective in maintenance: The design is almost maintenance free. Replacement of the resilient seal (disc edge) is the only major part to be changed out. - Smaller requirement for installation space

- Field approved safe design

- Low head-loss

- Can used for several types of applications

Easily replaceable O-ring shaft seals

Specific advantages of AVM SlantTech:

- The best combination for a check valve is

a – High eccentricity

b – Short stroke

This is achieved with this design - Optimum closing of rubber seat into the body seat

- Shear strain of the rubber seat much reduced due to the high eccentricity

- Sealing ring completely relieved from stress and wear in the open position

- The rubber seal is uninterrupted by shaft bearings etc

- The seal is easily replaced when the valve disc is open

- Replacement of the rubber seal is very economical and be done without dismantling of the valve

- The valve can be designed for higher working pressures, such as PN25 and PN40

- No risk for disc flutter (vibrations) by means of an unbalanced disc load

- Dashpot damper (bottom-mounted) is possible

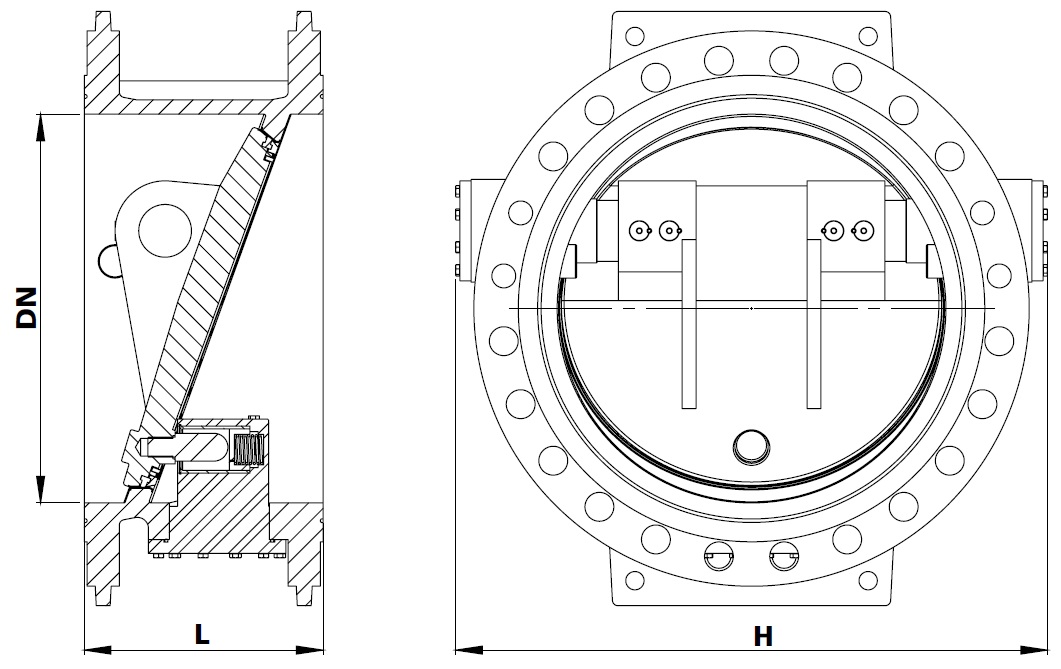

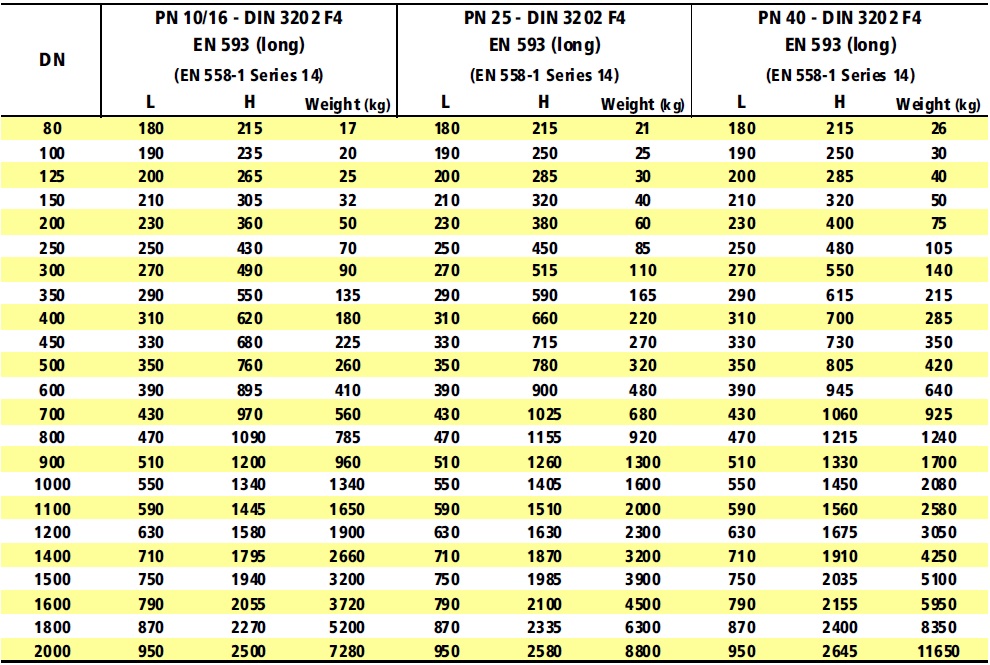

Size Range and Pressure:

DN150 to DN3000 as standard

PN6 to PN40 as standard

Some basic information: